MindMap Gallery The production method of calcium silicate

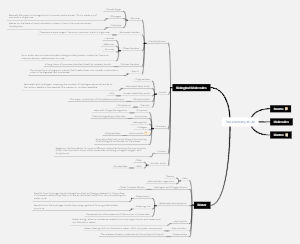

The production method of calcium silicate

In the production of calcium silicate, the ratio of silicon dioxide to limestone is precisely controlled to ensure the chemical composition of the product. High-temperature calcination is then performed to promote silicate formation. The reaction product is cooled and ground to obtain the desired silicate powder particle size. By adjusting reaction conditions and post-treatment steps, the morphology of the product, such as fibrous, granular, or blocky, can be controlled.

Edited at 2025-01-09 07:30:27The production method of calcium silicate

- Recommended to you

- Outline