MindMap Gallery Chemical products: Methods for making plastic bottles

Chemical products: Methods for making plastic bottles

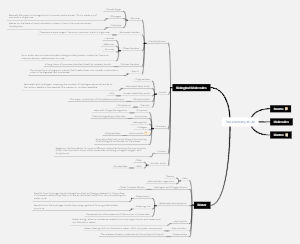

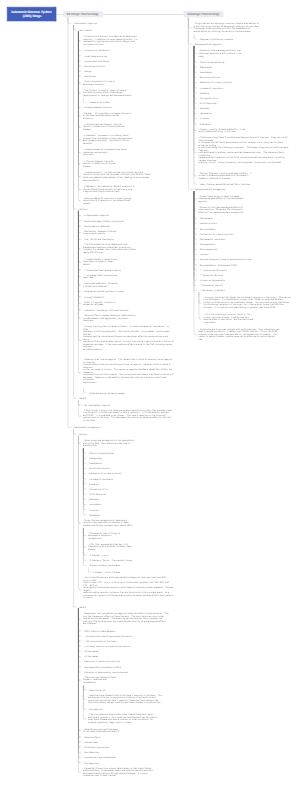

The methods for making plastic bottles begin with selecting high-quality plastic raw materials such as polyethylene (PE) and polypropylene (PP). These materials are melted at high temperatures and formed into continuous molten strands through an extruder. Subsequently, high-pressure air is used to blow the molten strands into a bottle shape, which is then cooled and shaped into the final plastic bottle. Finally, quality inspections are conducted on the plastic bottles, including checks on bottle wall thickness, seal tightness, transparency, and other critical indicators, to ensure that the product quality meets standards.

Edited at 2025-01-12 14:35:29Chemical products: Methods for making plastic bottles

- Recommended to you

- Outline