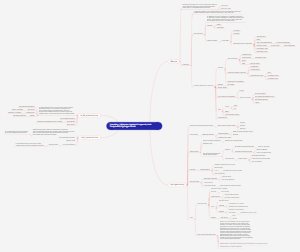

MindMap Gallery Chemical products: Manufacturing methods of rubber tubes

Chemical products: Manufacturing methods of rubber tubes

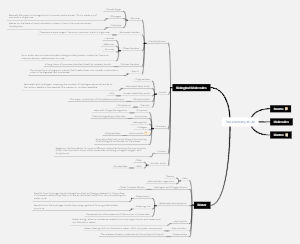

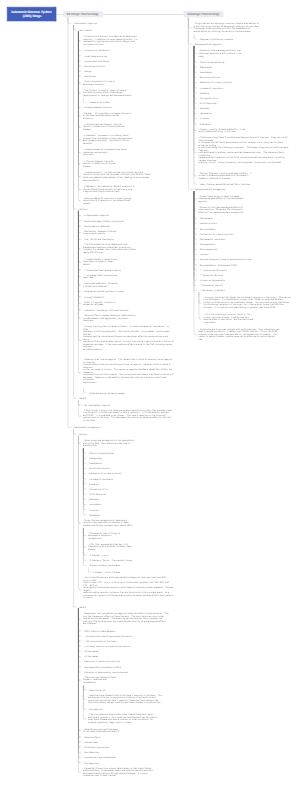

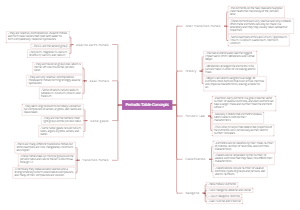

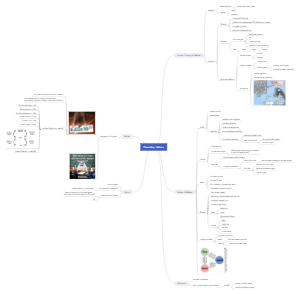

The manufacturing methods of rubber tubes involve steps such as raw material ratio, mixing and pressing, extrusion molding, vulcanization, and inspection and packaging. Firstly, the ratio of raw materials such as rubber base material, vulcanizing agents, and reinforcing agents is determined according to product requirements. After mixing, the raw materials are evenly combined and pressed into sheets. Subsequently, the rubber is extruded and molded at high temperatures through an extruder, with strict control over diameter and wall thickness. During vulcanization with steam or hot water, the rubber tube further solidifies and enhances its strength. Finally, hydraulic pressure tests and visual inspections are conducted to ensure no leaks or defects in the rubber tube, which is then packaged and shipped.

Edited at 2025-01-14 13:05:55Chemical products: Manufacturing methods of rubber tubes

- Recommended to you

- Outline