MindMap Gallery Food additive: production method of kaolin

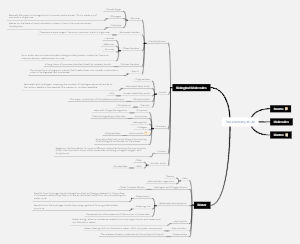

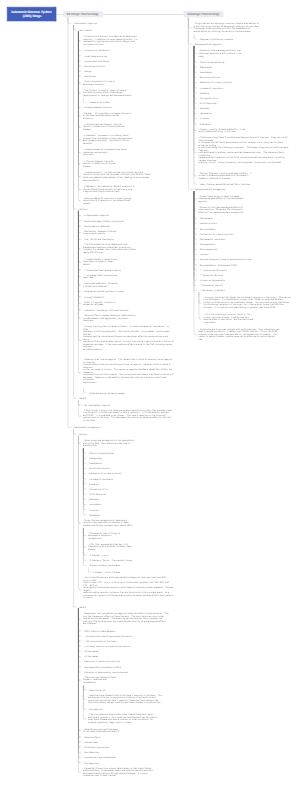

Food additive: production method of kaolin

The production method of kaolin involves raw material mining, grinding and mixing, calcination, wet processing, as well as drying and packaging. High-quality kaolin ore is first selected from mines. It is then finely ground to the desired particle size and adjusted in composition as needed. Subsequently, high-temperature calcination is performed to remove impurities and improve its properties. In the wet processing stage, water or other solvents are added for dispersion to achieve a more uniform product. Finally, spray drying is used to convert it into powder, and aseptic packaging is conducted to ensure product quality and hygiene.

Edited at 2025-01-14 14:07:54Food additive: production method of kaolin

- Recommended to you

- Outline