MindMap Gallery Aging optimization of 77% IN718 and 23% SS316L

Aging optimization of 77% IN718 and 23% SS316L

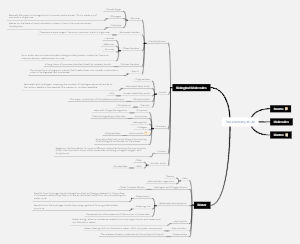

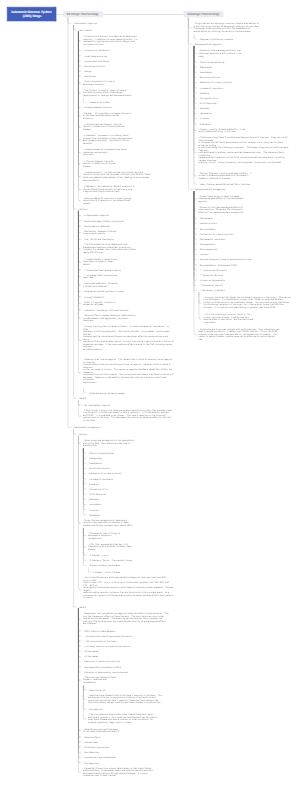

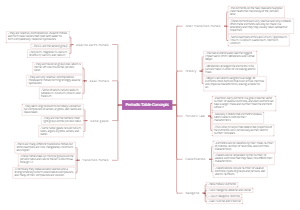

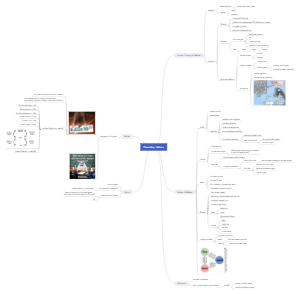

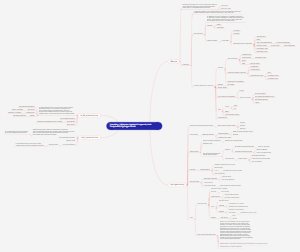

Aging optimization of 77% IN718 and 23% SS316L is a crucial process that aims to improve the material's performance and reliability. This alloy is composed of two main components: IN718, a nickel-based superalloy, and SS316L, a stainless steel. During aging optimization, the alloy undergoes a heat treatment process that enhances its mechanical properties. This treatment promotes the development of beneficial microstructural changes, leading to improved strength, ductility, and fatigue resistance. The optimized material is well-suited for high-temperature and corrosive environments, making it suitable for a range of demanding applications, including gas turbines, aircraft engines, and chemical processing equipment. This is a mind map of aging optimization of 77% IN718 and 23% SS316L. The map contains four main branches, which are: Printing long bars, Applying heat treatment, Microstructural investigation, Yield strength modeling calculations and initating machine leaming(Tasks 2 and 3). Each main branch is described by subbranches, and the relationship between the modules is indicated by a dashed blue arrow. For those interested in aging optimization.

Edited at 2023-07-24 14:32:06Aging optimization of 77% IN718 and 23% SS316L

- Recommended to you

- Outline